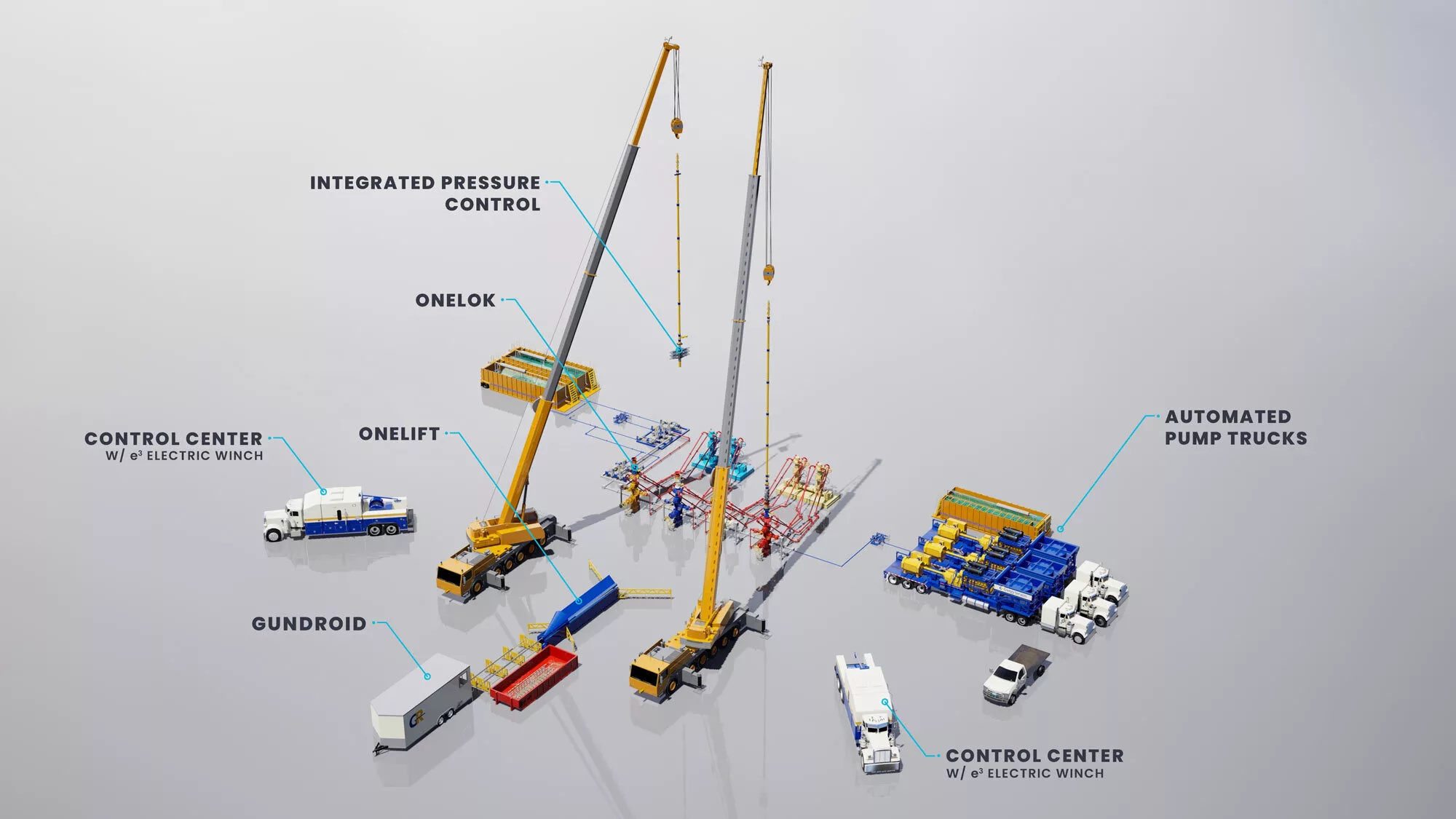

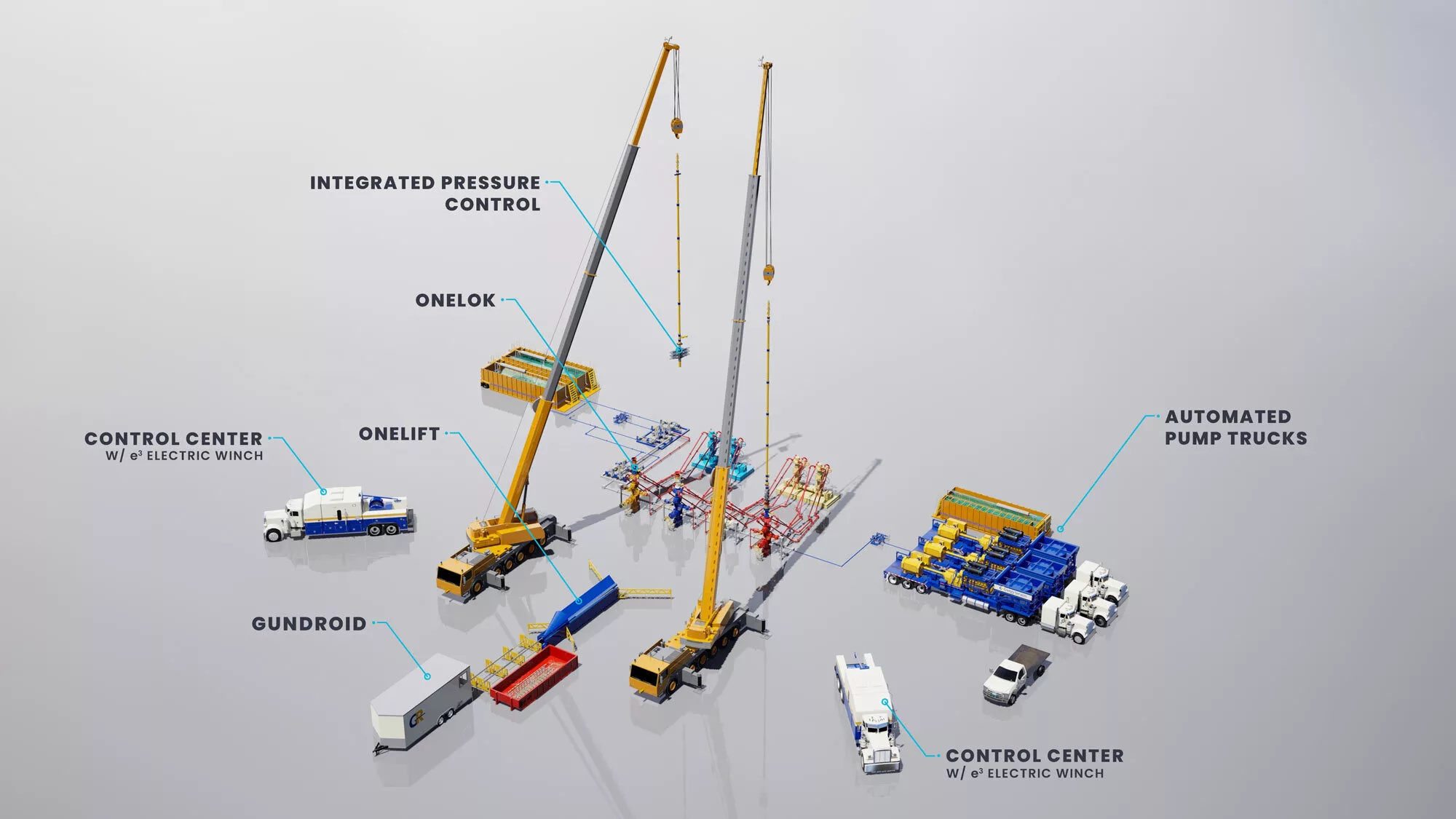

The first-ever fully integrated and automated system designed for wireline plug and perf operations. It incorporates state-of-the-art technology to streamline communication, enhancing efficiency and productivity.

To achieve efficient and precise delivery of downhole technologies, it is essential to bring together multiple pieces of equipment to function as a cohesive unit. This requires seamless integration and coordination of all equipment involved in wireline operations. When properly integrated and controlled through advanced software and automation systems, the equipment can operate as one, enabling repeatable operations and optimal downhole technology delivery.

Our Control Center serves as the central hub for directing wireline operations. The Control Center communicates with all downhole technologies and all intervention solutions, including our automated perforating gun assembler, gun lift, winch package, pressure control equipment, and pumpdown units, ensuring that wireline operations are conducted with precision and efficiency.

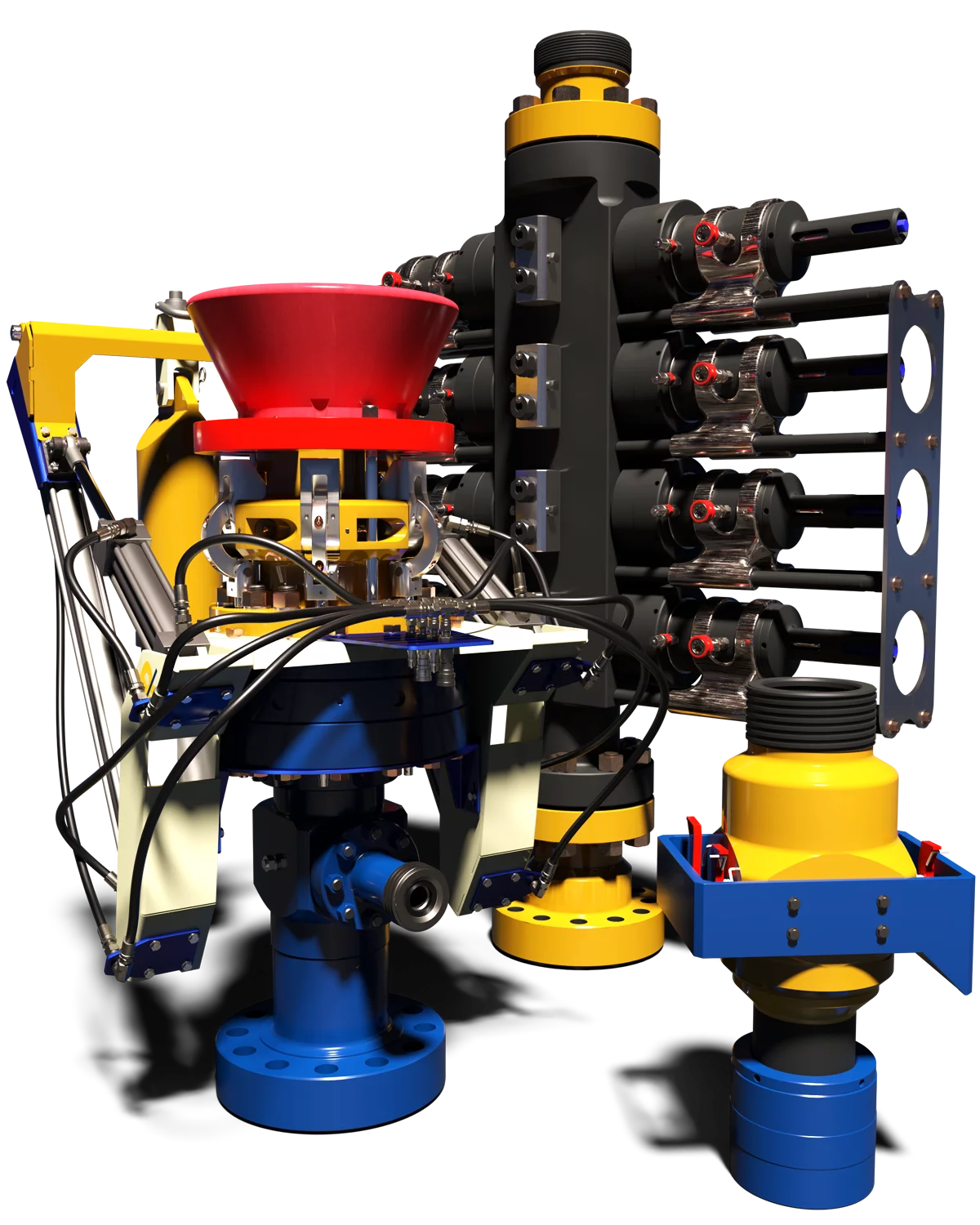

We are proud to introduce our state-of-the-art robotic unit, designed to provide unparalleled wellsite operation capabilities. This advanced unit is equipped with sophisticated technology that meticulously examines and automates various processes, delivering unmatched levels of precision and efficiency. Unlike traditional methods that often require personnel and expose them to safety risks, our robotic unit is fully automated, mitigating such concerns and minimizing the likelihood of errors.

Our unit provides a highly efficient and reliable solution for your wellsite operation needs, maximizing productivity and minimizing downtime for consistent, high-quality output. Its state-of-the-art features make it an ideal choice for those seeking to enhance their operational capabilities and streamline their processes.

Electric wireline units are a superior choice for both the environment and operational efficiency. As fully electric-powered units, they offer a cleaner and more sustainable option compared to traditional wireline units. The advanced automation capabilities of electric wireline units allow for seamless integration with pump-down units, enabling precise control of torque to maintain constant tension and ensure reliable and repeatable conveyance for efficient delivery of downhole technologies. These units also provide enhanced safety features to prevent accidents and reduce risks to personnel and equipment.

Designed to enable faster running speeds and rig-up times, our grease-free electro-mechanical wireline cable eliminates maintenance and environmental risks while providing superior performance. Our Greaseless Wireline is ideal for cased hole horizontal completions and extended reach wells, with a torque-neutral design that reduces downtime and maintenance costs. With a unique armor package design and rugged polymer jacket, it can handle up to 375°F and has an impressive 8,500 lbs break strength. The water blocked stranded copper and high-temperature fluoropolymer dielectric conductor ensure longer-lasting performance and reduced surface tension, even on longer deviated wellbore laterals.

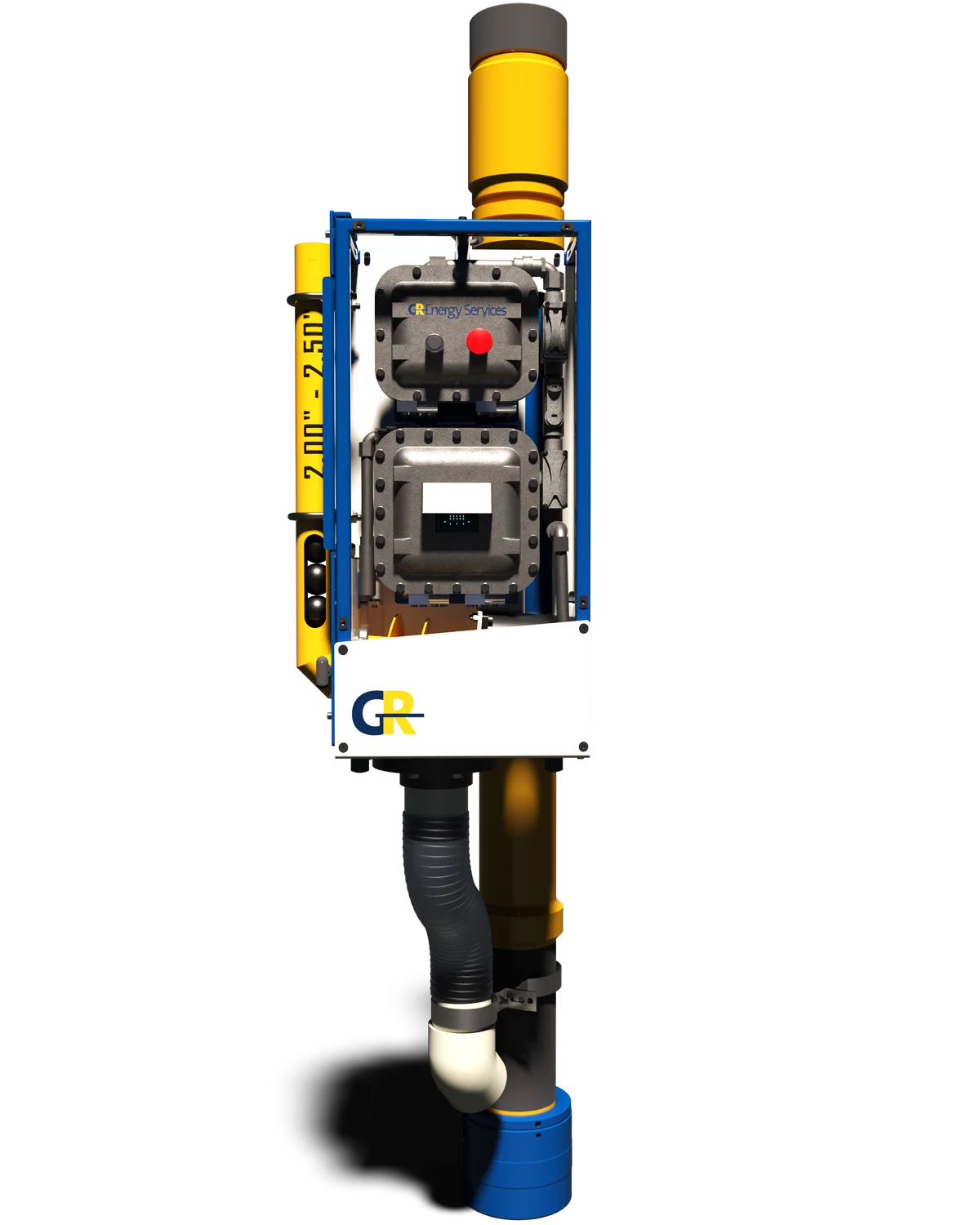

Our advanced pumpdown controls are the cornerstone of our wireline operations, providing exceptional automation and real-time feedback. Our technology seamlessly integrates with our Control Center, allowing for complete synchronization with your wireline unit. This integration provides nuanced options for precise timing and reliable repeatability, while simultaneously reducing the risk of mishaps during wireline operations.

Our real-time connection enables the system to act immediately, making critical decisions to maintain high output and minimize risk. Additionally, our pump-down units are equipped with hibernation modules that significantly reduce diesel fuel requirements, thereby lowering the carbon footprint and optimizing maintenance cycles.

Trust our advanced pumpdown controls to lead the way in driving your wireline operations to new heights.

Our pressure control packages are available in 10K, 12.5K, and 15K and are fully certified to meet API Spec 16B and NACE MR0175 standards, providing customers with the best equipment for the job.

We take efficiency and safety seriously, which is why we offer the OneLok wellhead hydraulic latch equipment. Our OneLok system streamlines the process of connecting and disconnecting the wireline lubricator to the wellhead, significantly reducing well transition time. With remote hydraulic actuation, customers can be sure that personnel won’t have to engage in hazardous manual connections above the wellhead, ensuring their safety at all times.

By utilizing our OneLok equipment, customers can effectively reduce operating time and protect personnel from injuries that can occur during well transition operations. Our commitment to safety and providing efficient solutions for wireline needs is what sets us apart. At GR Energy Services, we make sure that proper pressure control measures are always in place for safety at the wellsite. Choose us for reliable and safe wireline operations.

OneLift is designed to safely lift and lower tool and gun assemblies with controlled movement, reducing potential injuries and equipment damage. It allows a single operator to work without the potential dangers of working under suspended loads and avoid unnecessary damage to wireline and tools. OneLift has upper restraints and a wide funnel receptacle to guide the assembly, which sits against the corrugated channel.

OneLift is then hydraulically activated by a remote operator to lower from 80 degrees to completely horizontal. Once lowered, the funnel cap is removed and the assembly is extended to an ideal, average working height. OneLift can lift and lower tool and gun assemblies up to 1,000 lbs and supports gun lengths up to 45 ft. It creates a natural barrier from danger zones and offers an ideal average working height. OneLift eliminates the risk of injury in a routine procedure and extends gun-building capability at the wellhead.

OptiDrop, developed by experts in the industry, is an optical remote ball dropper that optimizes safety, wellsite efficiency, and transition time between frac stages. The proven technology has been integrated to help operators increase total available pumping time, reduce risk, and lower the total cost of operations.

Unlike conventional plug-n-perf operations that require personnel to work at heights to deploy frac balls by hand, OptiDrop equipment safely deploys balls with a high-powered, infrared, remotely controlled trigger mechanism. Pulses of infrared light, which are invisible to the human eye, are highly reliable and ensure a perforating-safe environment. A long-range visual drop indicator is visible in all weather conditions, and an induction-based sensor detects ball drops. A green LED window indicates a successful drop, and a red light indicates a ball drop did not occur.

Specifying OptiDrop equipment for frac and refrac operations locks in several advantages: